Trucks and buses

The standard remanufacture of power steering boxes, that are assembled in trucks and buses includes:

- External washing.

- Disassembly.

- Washing of parts.

- Verification of the parts:

- Checking up if they don't hale any visible damages,

- Size check up,

- Play check up,

- Screw threads check up.

- Check up with the use of metallograpgic defectoscope whether they have any microfractures.

- The exchange of all seal kits.

- Rubbing down of co-operating surfaces, if they have any visible fractures.

- The exchange of all ball bearings co-operating with wormgear and piston.

- The exchange of used bumper rods.

- Assembly.

- Check up on a diagnostic computer stand ASBPKO1, which simulates real work conditions of a steering box. If the test result is negative the steering gear is being remanufactured once more. If the test result is positive, next procedures include:

- Painting of a steering unit.

- Sealing (in the way that any unauthorised attempt of overhaul will execute breaking of the seal).

- Permanent stamping of an earlier given number.

Each steering unit, remanufactured at our company has its' own identity card with parts register, that have been used for remanufacturing.. If the measurement didn't fit in the tolerance field the parts need to be exchanged. (a standard remanufacture doesn't include potential exchange of steering gear's shaft, piston, bearing pad shaft and housing).

Besides that all steering gears have their examination card, which include all results of the measurement begining with play, and on characteristics ending (work diagram of steering unit under load).

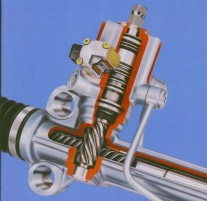

Passenger cars

A standard remanufacture of rack and pinion steering gear assembled in passenger cars and vans includes:

- External washing.

- Disassembly.

- Washing of parts.

- Verification of the parts:

- Checking up if they don't hale any visible damages,

- Size check up,

- Play check up,

- Srew threads check up.

- Check up with the use of metallograpgic defectoscope whether they have any microfractures.

- The exchange of all seal kits.

- Rubbing down of co-operating surfaces, if they have any visible fractures.

- The exchange of all used ball bearings.

- Assembly.

- Check up on a diagnostic computer stand SD-WW01, which simulates real work conditions of a steering box. If the test result is negative the steering gear is being remanufactured once more. If the test result is positive, next procedures include:

- Painting of a steering unit.

- Permanent stamping of an earlier given number.

- Transport of steering gear to final-goods store-house.

Each steering unit, remanufactured at our company has its' own identity card with parts register, that have been used for remanufacturing.. If the measurement didn't fit in the tolerance field the parts need to be exchanged. (a standard remanufacture doesn't include potential exchange of steering gear's shaft, rack and housing).

Besides that all steering gears have their examination card, which include all results of the measurement begining with play, and on characteristics ending (work diagram of steering unit under load).